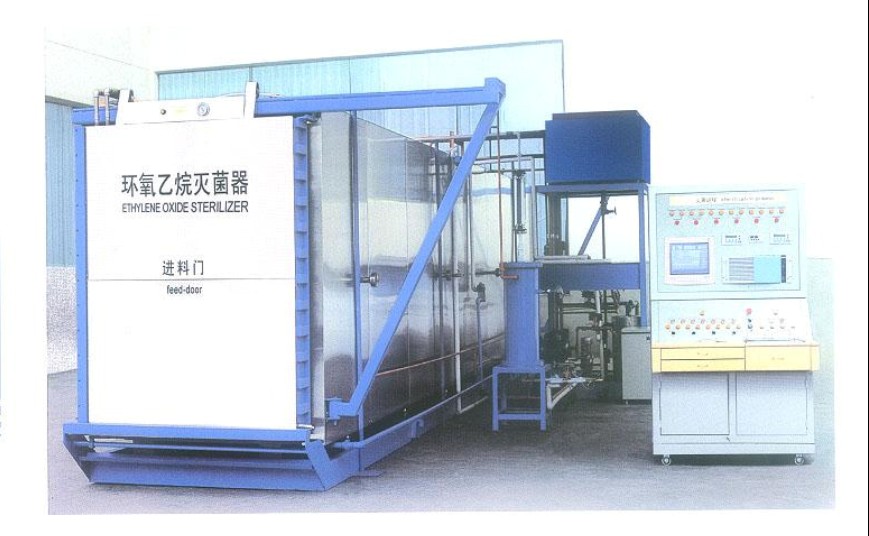

Main Technical Parameters of HD-EN-20 EO Sterilizer(In Conformity with EuropeStandard EN 1422)

|

Volume of inner container |

20 / 10 / 6 / 3 M3、 |

|

Size |

Inner container: W135´H170´L900 (cm)//135x170x450//135x170x280//100x165x185 Outside : W190´H240´L945 (cm)//190x240x495//190x240x325//155x235x230 |

|

Material of case body |

Stainless steel: inner container 8 mm, outside shell 1.2 mm |

|

Sterilizing temperature |

0~100°C, PID adjustable |

|

Sterilizing pressure |

-95~+80 Kpa |

|

Sterilizing humidity |

20~100% RH, adjustable |

|

EO concentration |

300~1000 mg/L |

|

Sterilizing time |

3~12 hrs |

|

Pre-vacuum |

-90 Kpa |

|

Times of air change |

Arbitrarily |

|

Ventilation time |

Arbitrarily |

|

Max. electrical heating power |

55 KW //41kw//20kw//15kw |

|

Max steam heating power |

10 KW |

|

Power source |

3-phase, 4-wire, 380 V, 50 Hz or 220v, 60Hz |

|

Whole process automatic control by computer |

Two-level control: Siemens Industrial control computer + Siemens PLC 1. Automatic door opening and closing (shifting type), automatic air-inflation sealing; 2. Automatic control of whole sterilizing process 3. Automatic alarming and safe protection |

|

Main attachments |

1. Vacuum system (sterilizing pre-vacuum, washing after sterilization, relief of door sealing) 2. Heating and hot water circulation system (heating of sterilizing case body, preconditioning of goods to be sterilized, temperature holding) 3. EO gasifying and automatic dosing (gas mixing) system (EO medicine, N2and CO2mixing though heat interchange and gasification) 4. Automatic humidifying (steam generator) system ( Humidity preconditioning of goods to be sterilized) 5. Pneumatic system and automatic door-opening and closing devices (Control of automatic open and close of valves and doors, self-lock and interlock of doors, and automatic sealing of doors) 6. Residual gas treatment system (Neutralization treatment of the residual gas) 7. Automatic alarming and safety test protection system 8. Display, control, record, printing, save and inquiry of the sterilizing parameters and tendency chart |

20m2Ethylene Oxide Sterilizer (CE Standard)

1. Installation: The supplier shall assist the buyer with arrangement of the installation location and be in charge of on site installation, debugging and trial sterilizing of the equipment free of charge. While the buyer shall take the duty to erect switch cabinet and introduce the power cable, steam pipeline, inlet and outlet pipeline into the sterilizing room according to the requirement of the supplier. (The connection of the power cable and join of the inlet and outlet pipes are to be accomplished by the supplier.)

2.After the completion of the installation, debugging and trial sterilizing, the buyer will organize related technical personnel to test the performance of the equipment and conduct acceptance according to European Standard EN550 (Validity and Normal Procedure Control for Sterilization of Medical Apparatus with Ethylene Oxide ).

3. Maintenance: The equipment is a guaranteed for a period of one year and enjoys a lifelong service. During the guarantee period (within one year since the delivery of the equipment), the supplier should supply fittings to the buyer free of charge. The key attachments like computer control and management software, and spare parts which are apt to wear down, such as sealing bars and electrical heating tubes, shall be provided with the equipment together.

4. Training & technical support: The supplier will be responsible for operator training free of charge in operation and maintenance of the equipment, safety knowledge and sterilizing technology.