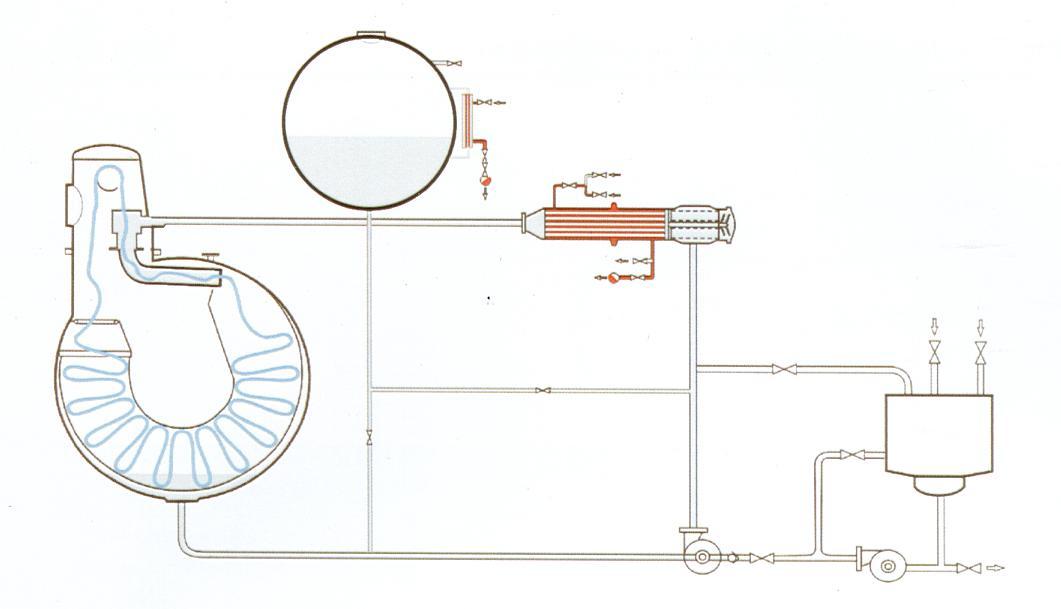

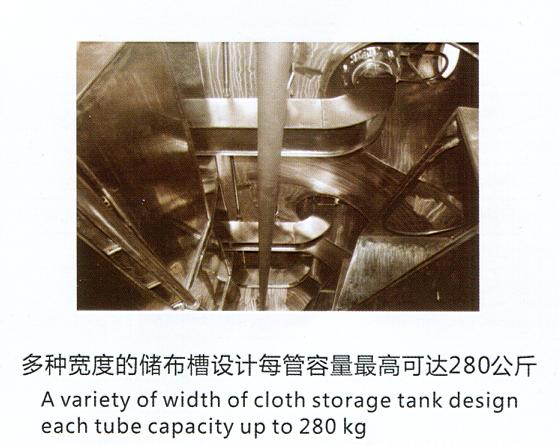

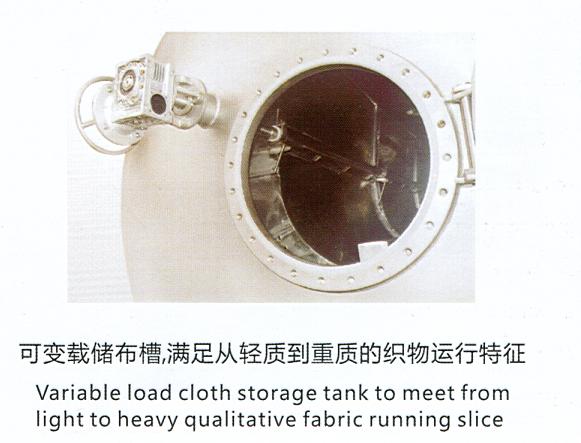

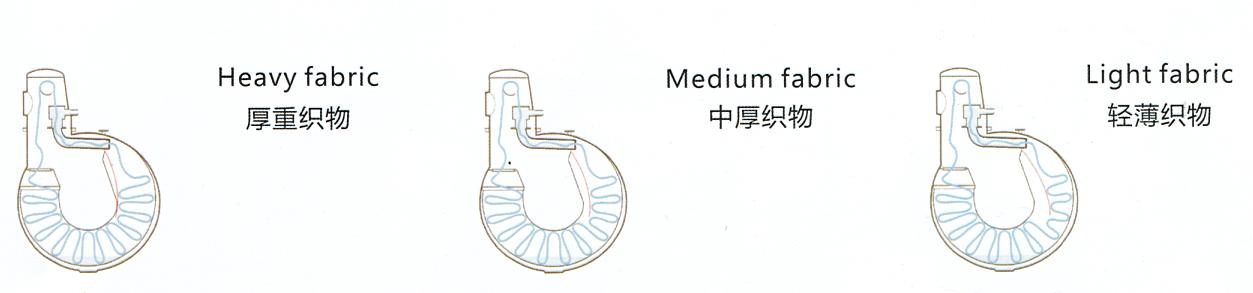

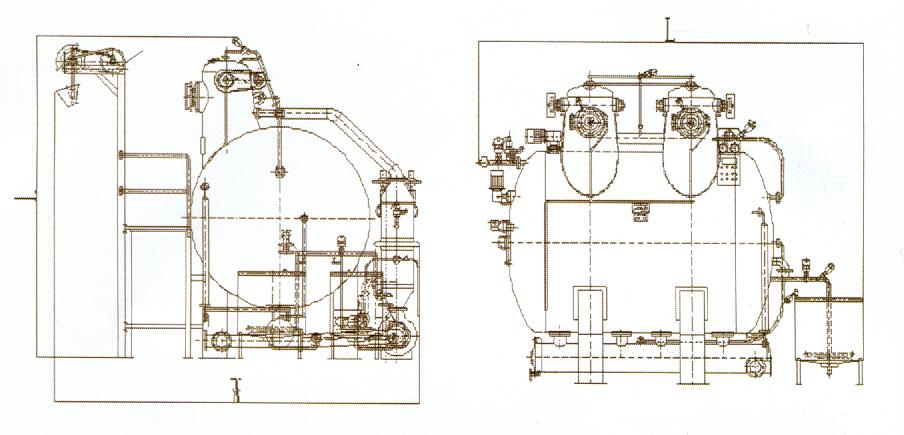

It is a new development of a new generation of high temperature dyeing machine, set a number of research results, can reach the lowest line machine when loaded with water than 1:4.5, to reduce energy consumption, shorten dyeing time, to ensure high quality of dyeing fabric. Adjustable cloth storage tank device*(ADC), dyeing light cloth kind to heavy cloth can ensure smooth operation, cooling water washing step method (CIR*), cooling and cleaning procedures, reduce the dyeing time, emissions and water consumption, large capacity of groove design, make each tube cloth tank capacity up to 280Kg, optimize the structure design and make the 1:5 bath ratio dyeing cotton fabric smoothly.

Technical Data

|

Packed with single machine water than |

1:4.5 |

|

Most big step speed |

380m/min |

|

Capacity |

100-2240Kg |

|

Max. Working Temperature |

140℃ |

|

Max. Working Pressure |

3.5 bar |

|

Heating Rate |

25℃ to 100℃, 5℃ per minute on average 100℃ to 130℃, 2.5℃ per minute on average (Dry saturated steam pressure 7 bar) |

|

Cooling Rate |

130℃ to 100℃, 3℃ per minute on average 100℃ to 85℃, 2℃ per minute on average (Cooling water pressure of 3KG/cm2, the temperature lower than 25℃ |

Adjustable Fabric Storage Chamber

|

Machine Configuration |

Standard |

|

All the fuselage and dyeing liquid contact plate adopt plate for SUS316TI/SUS316L highly Corrosion resistant stainless steel manufacturing |

√ |

|

Highly efficient stainless steel centrifugal pump |

√ |

|

The Main pump frequency conversion controller |

√ |

|

The ADC variable loads of cloth storage tank |

√ |

|

Frequency conversion control hoisting drum |

√ |

|

Multistage dyeing nozzle |

√ |

|

Fabric cloth groove roll fold device |

√ |

|

High efficiency heat exchanger configuration can cooling control system |

√ |

|

Equipped with a digital sensor level indicator |

√ |

|

Programmable automatic quantitative loading and chemical fertilizer system |

√ |

|

Roller fabric involution since the lifting device |

√ |

|

Built-in circulating spray cleaning device |

√ |

|

With DTR in both Chinese and English display dyeing control computer of electrical control box |

√ |

|

What cloth roller shoe anti-slip matt surface glue |

√ |

|

Stainless steel working platform with antiskid rubber sheet |

√ |

|

The spare filter sieve |

√ |

|

The fuselage rapid pressure and pressure system |

√ |

|

Multi-core control cables |

√ |

|

CIR Colling water washing step method |

Optional |

|

With the function of circulation and quantitative feeding the second paint bucket |

|

|

Multi-function prepare cylinder |

|

|

Cloth detector |

|

|

The cloth roll fold |

|

|

Additional line length |

|

|

Programmable analog measurement into the water |

|

|

Tandem device |

|

|

Programmable second enters the water/programmable second drainage |

|

|

Only low water overflow wash water washing water and intelligence |

|

|

PFD line pump fast drainage method |

|

Model |

Chamber Width |

Nominal Capacity |

|

Number of Chamber(mm) |

|||||

|

|

1 |

2 |

3 |

4 |

6 |

8 |

|||

|

FB100 |

600MM |

100KG |

|

100KG |

— |

— |

— |

— |

— |

|

L |

1250 |

— |

— |

— |

— |

— |

|||

|

W |

3500 |

— |

— |

— |

— |

— |

|||

|

H |

2900 |

— |

— |

— |

— |

— |

|||

|

FB150 |

600MM |

150KG |

|

150KG |

300KG |

450KG |

600KG |

900KG |

1200KG |

|

L |

2935 |

3535 |

4150 |

4800 |

6225 |

7315 |

|||

|

W |

4610 |

4650 |

4650 |

4720 |

4725 |

4725 |

|||

|

H |

3880 |

3880 |

3880 |

3880 |

3880 |

3880 |

|||

|

FB200 |

800MM |

200KG |

|

200KG |

400KG |

600KG |

800KG |

1200KG |

1600KG |

|

L |

2940 |

3750 |

4550 |

5350 |

6950 |

8585 |

|||

|

W |

4685 |

4725 |

4725 |

4795 |

4795 |

4835 |

|||

|

H |

3880 |

3880 |

3880 |

3880 |

3880 |

3880 |

|||

|

FB250 |

1000MM |

250KG |

|

250KG |

500KG |

750KG |

1000KG |

1500KG |

2000KG |

|

L |

3150 |

4750 |

5150 |

6300 |

8500 |

10700 |

|||

|

W |

4685 |

4725 |

4725 |

4795 |

4795 |

4835 |

|||

|

H |

3880 |

3880 |

3880 |

3880 |

3880 |

3880 |

|||

|

FB280 |

1250MM |

280KG |

|

280KG |

560KG |

840KG |

1120KG |

1680KG |

2240KG |

|

L |

3350 |

4700 |

5950 |

7250 |

9850 |

1243 |

|||

|

W |

4685 |

4910 |

4950 |

4950 |

5150 |

5200 |

|||

|

H |

3880 |

3880 |

3880 |

3880 |

3880 |

3880 |

|||