FB820 series of Heat-Setting Stenter

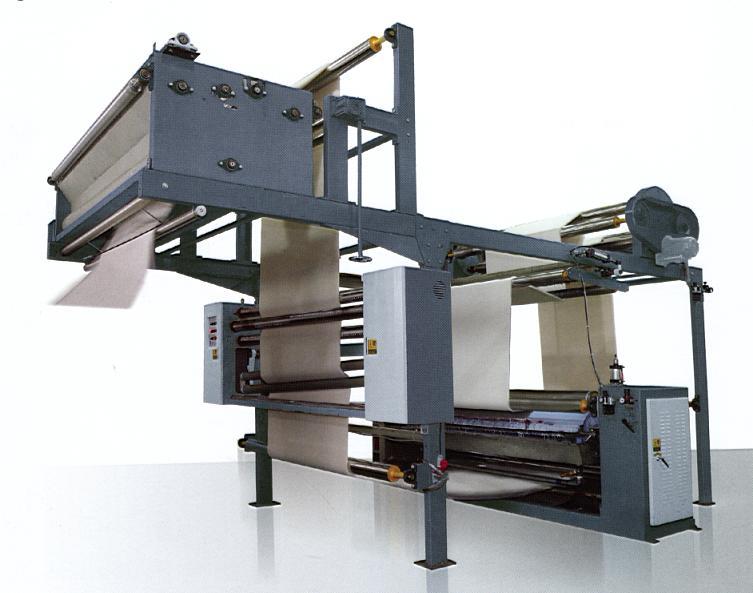

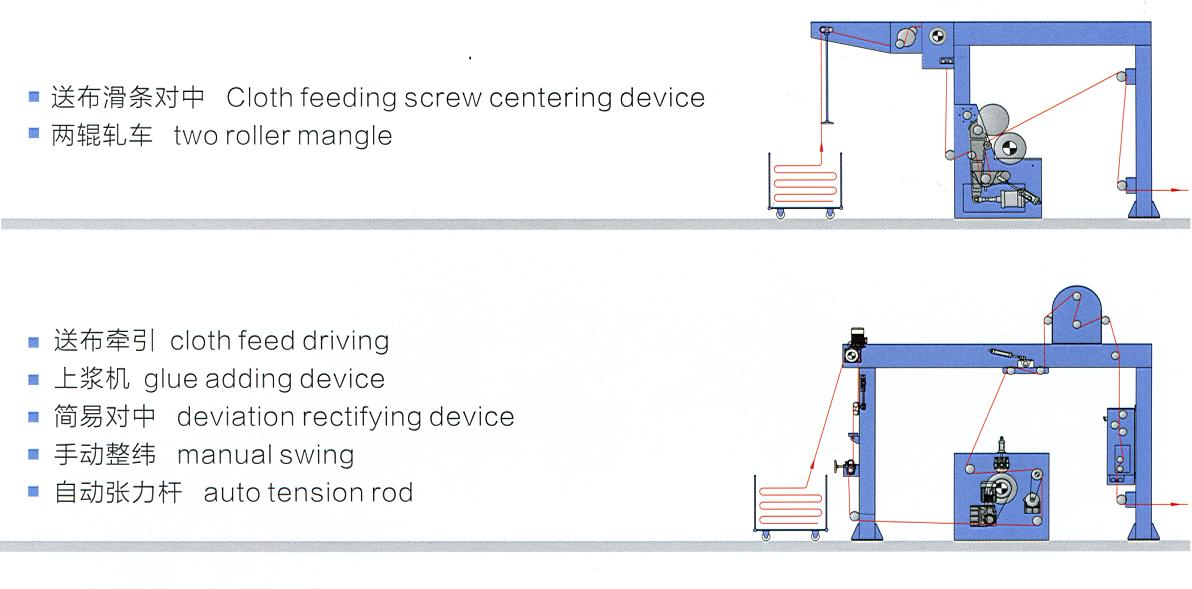

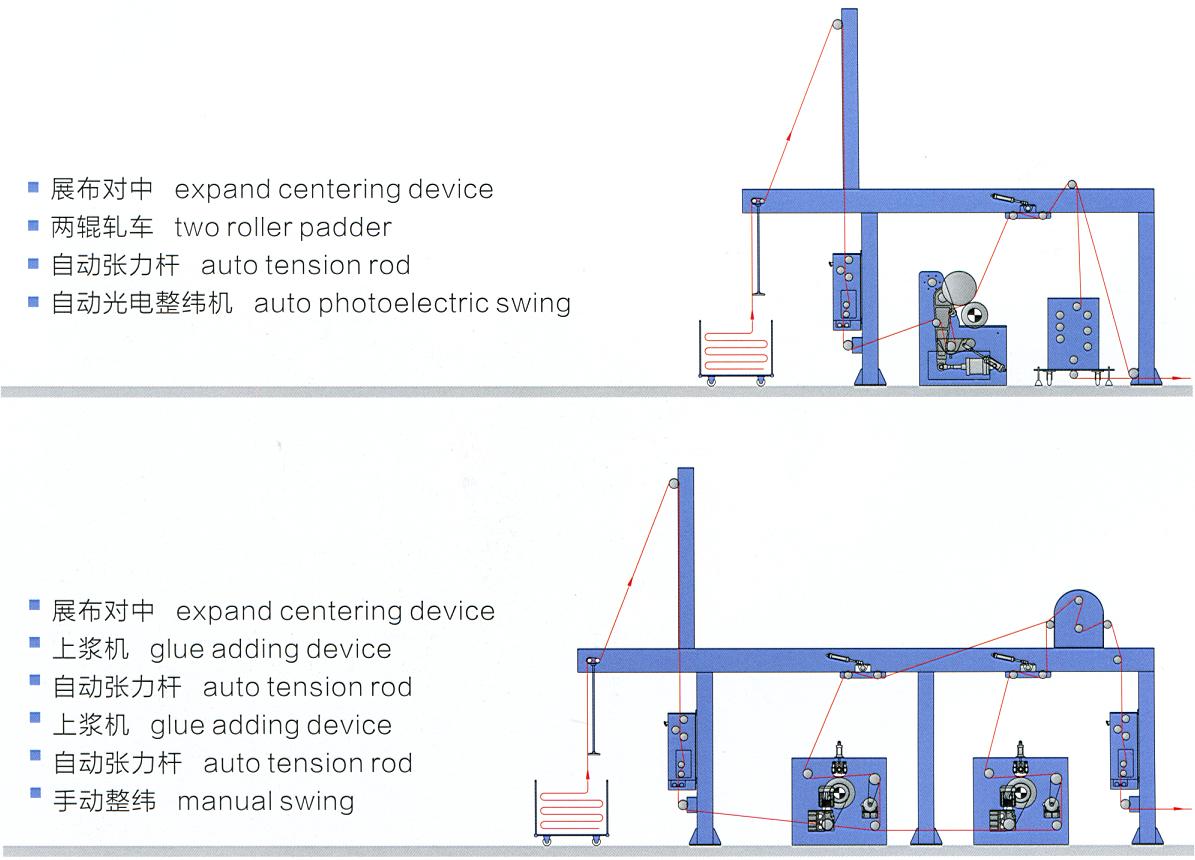

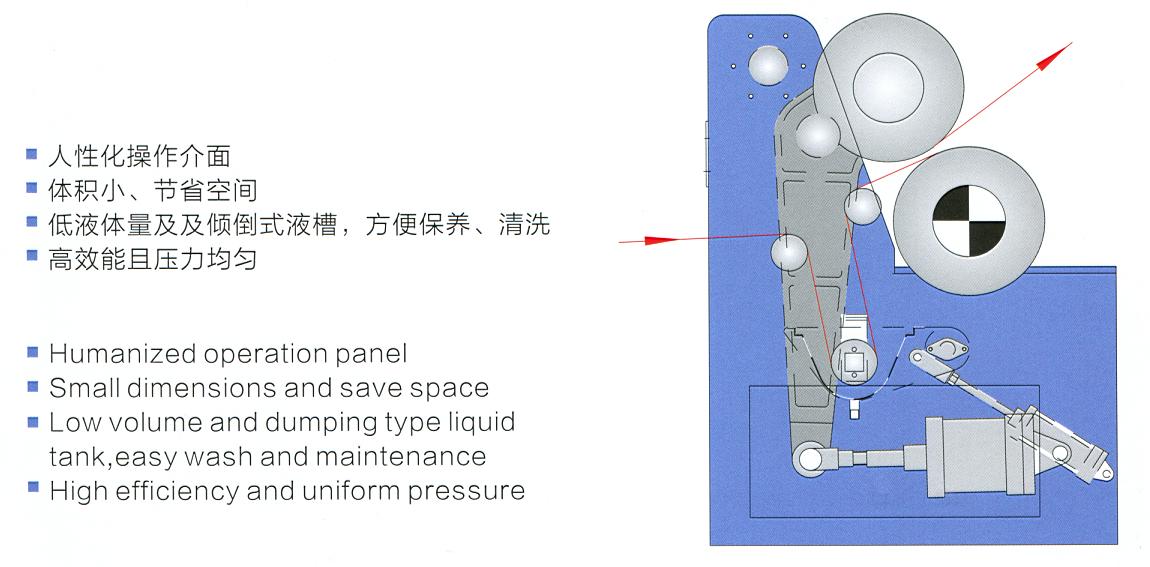

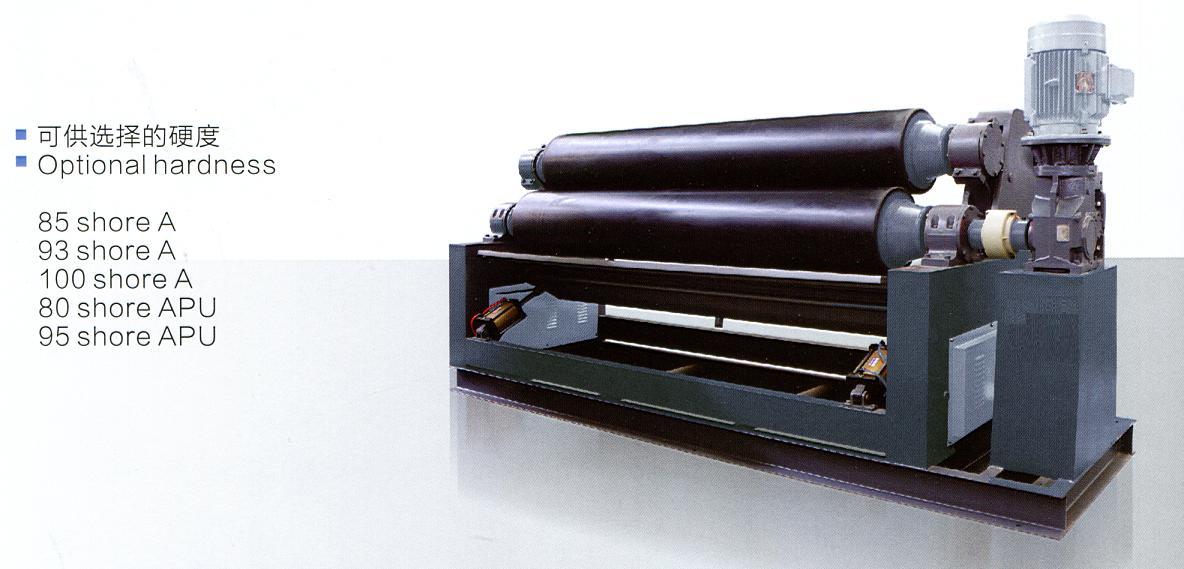

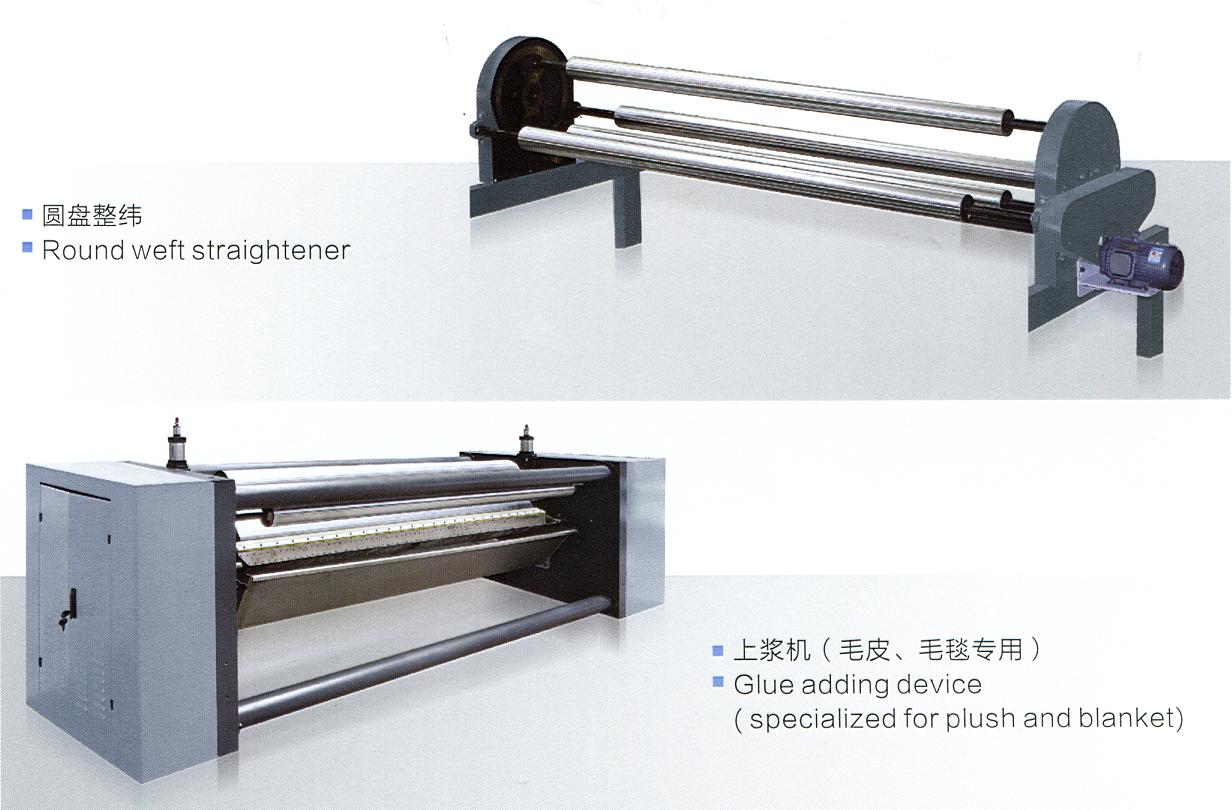

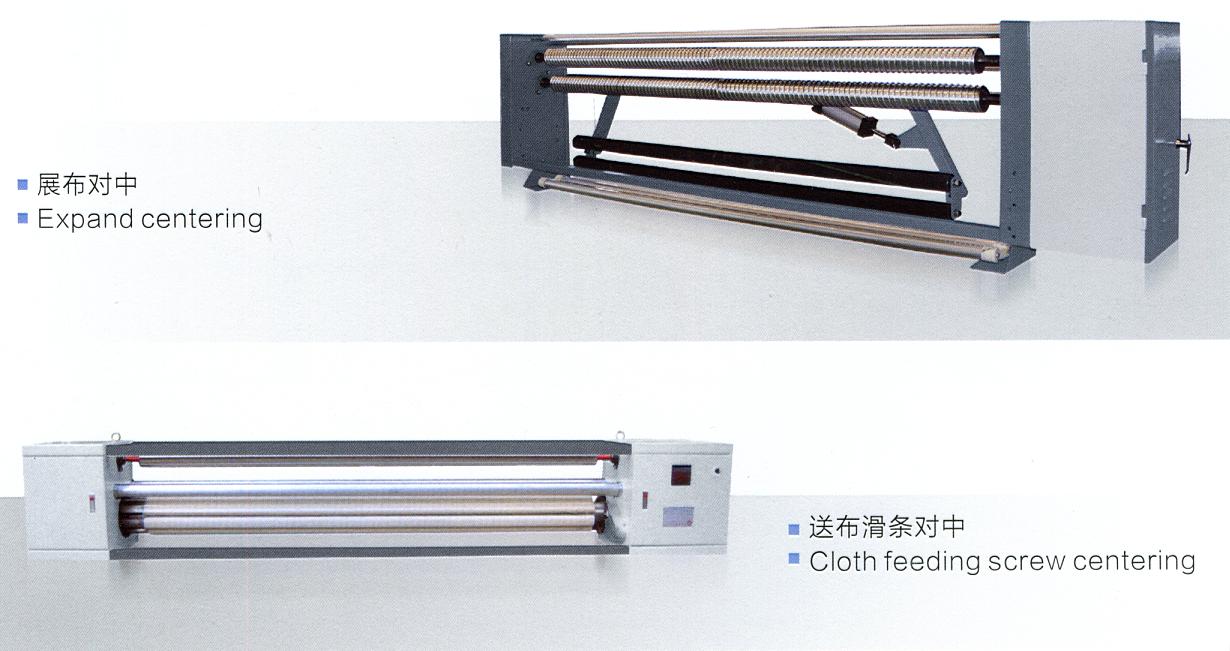

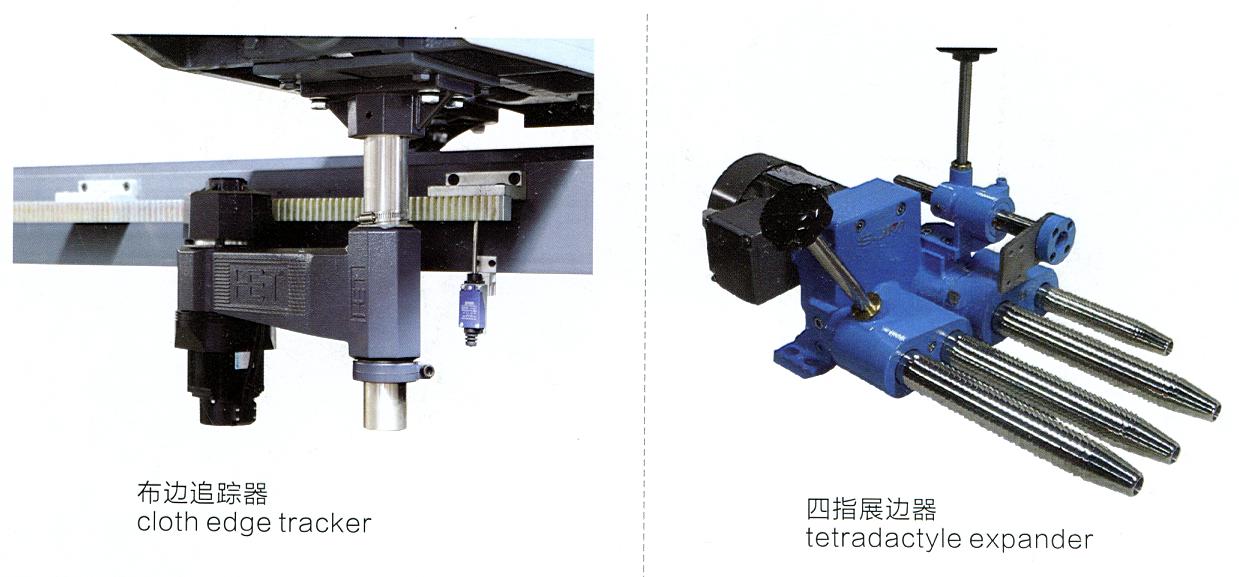

Feeding Part

1. Upon different fabrics and craft requires, we design different feeding part.

2. We design minimum fabric feeding tension, more evenly glue adding and softening process.

Overfeed Part

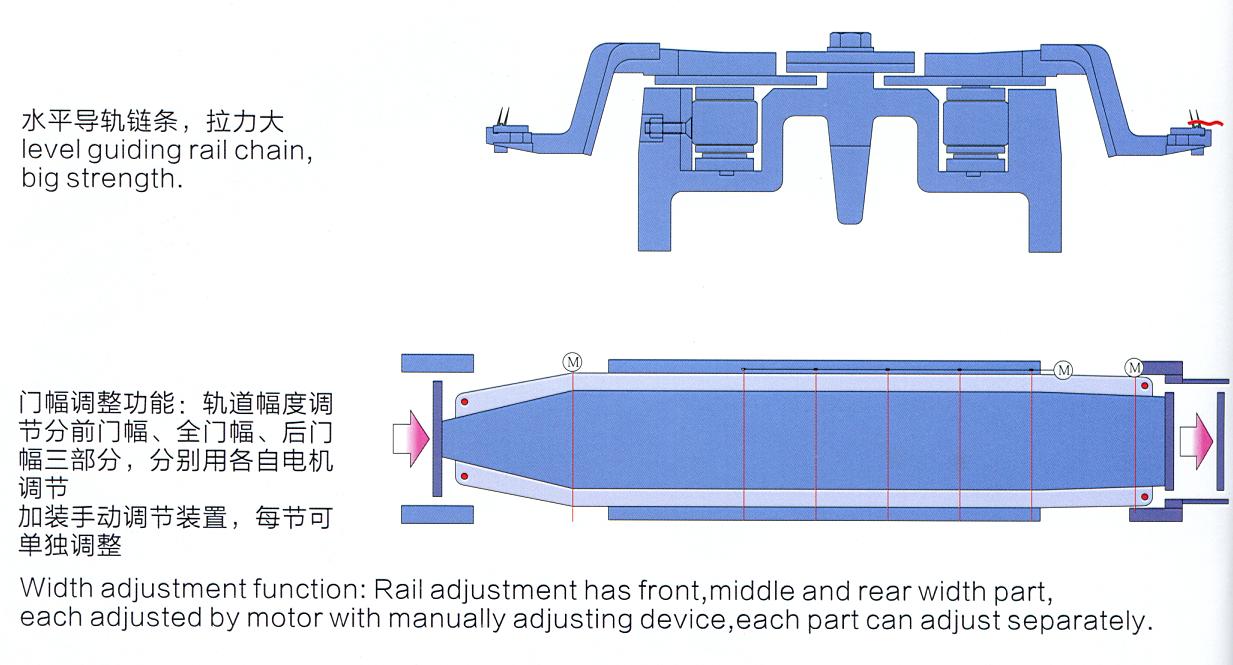

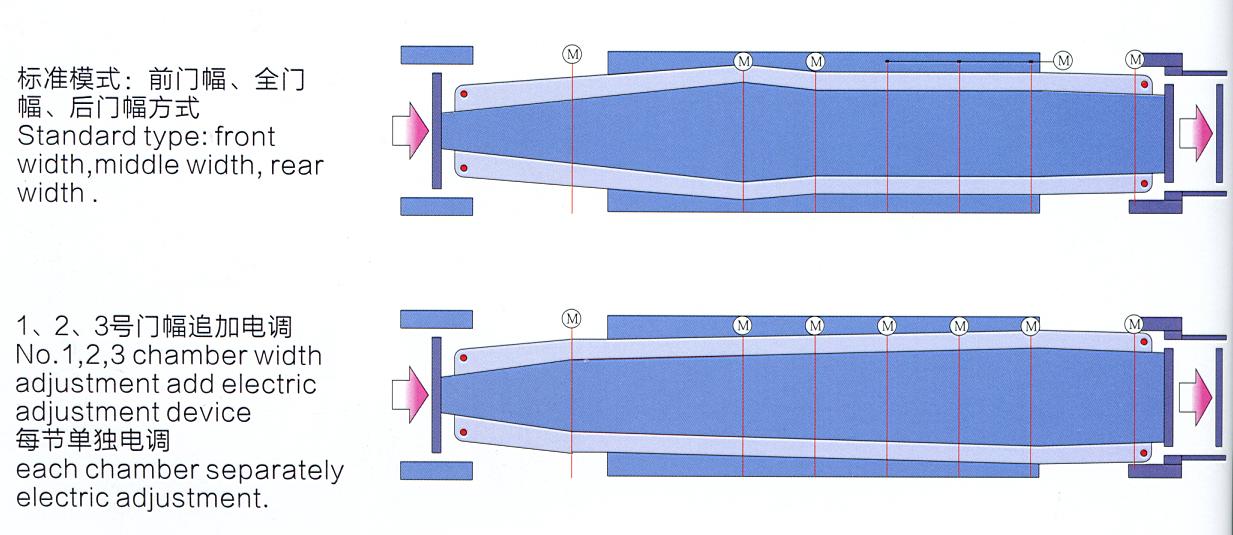

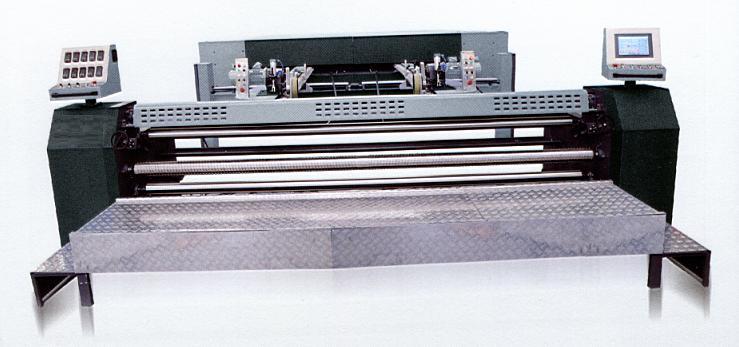

Width Adjustment Part

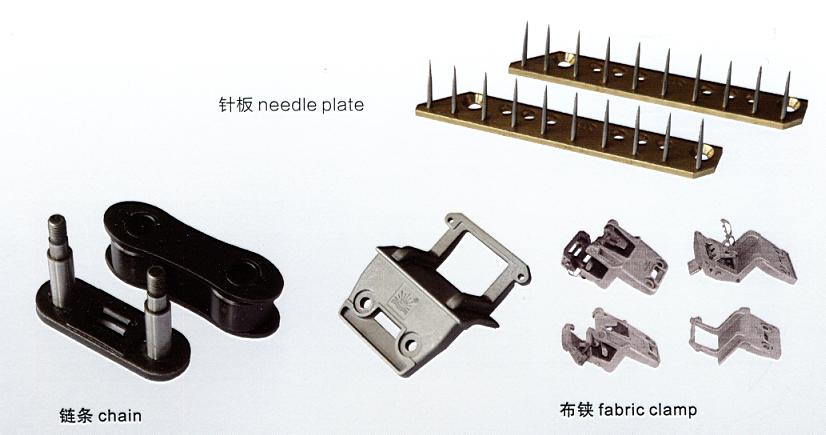

Casting iron guiding rail, inner manganese steel wearable plate

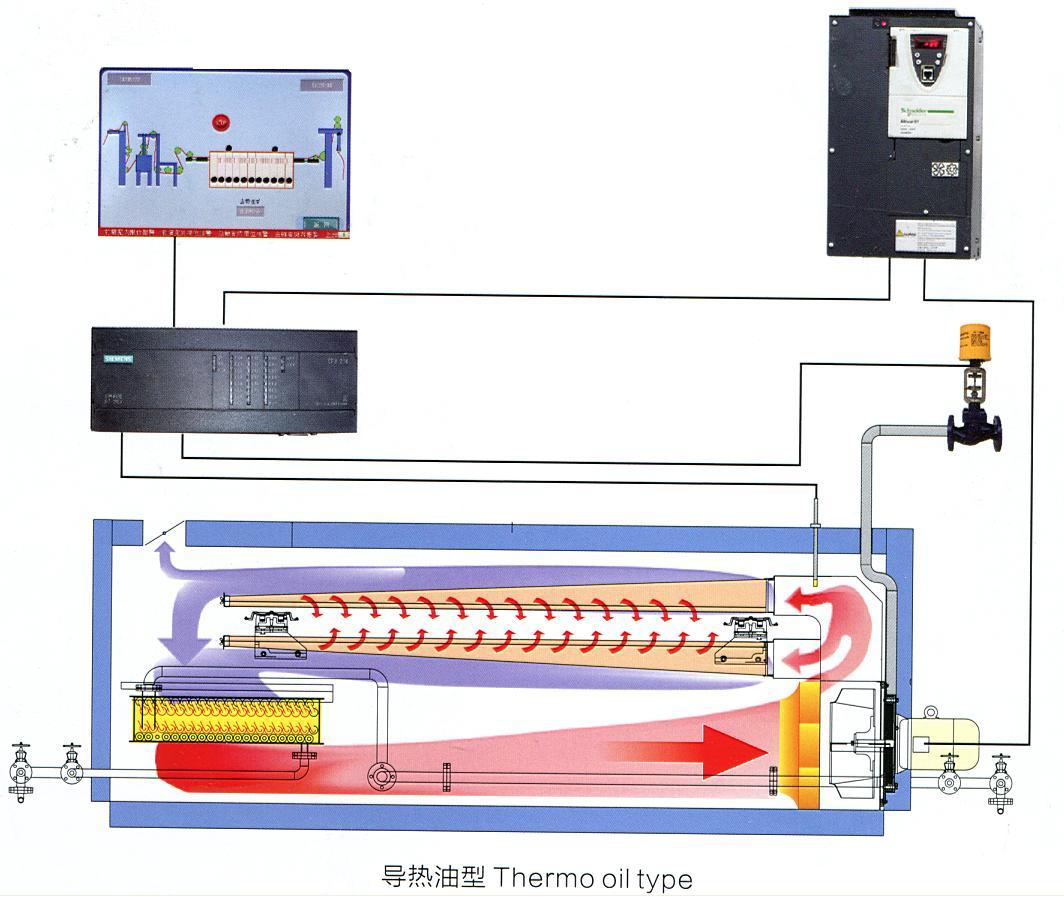

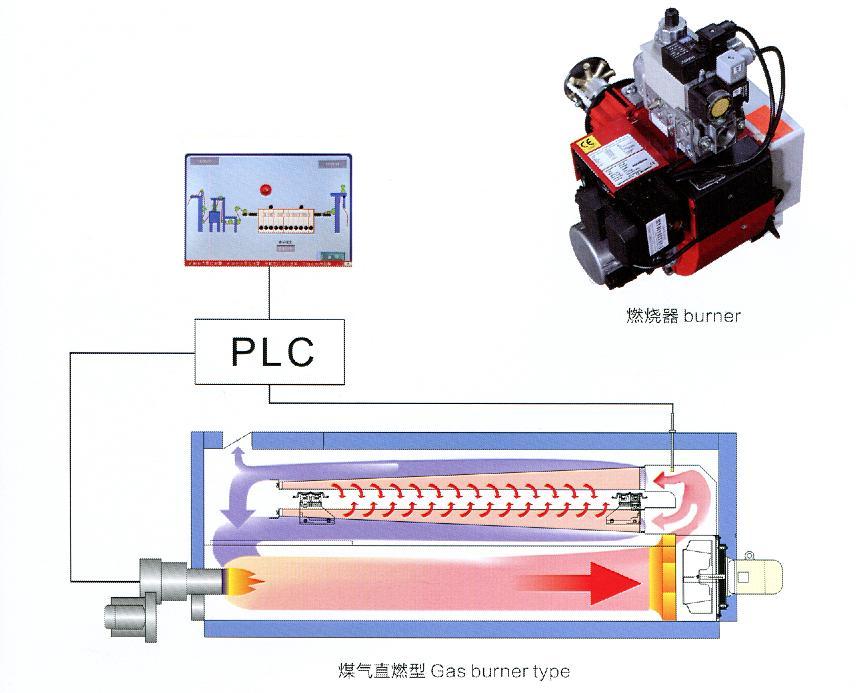

Heating Air Circulation

1. Uniform temperature of chamber: Adopt partition plate to separate nozzle part and heating air circulating part, completely block heat from radiation, get temperature even in different parts.

2. Heat Preservation: Adopt new type material with 150mm plate for heat preservation, reduce gap between plates, making exhaust pipes and chamber to be a complete part, save 10% energy.

3. Gas burner: High quality burner with vague digital control air-fuel ratio, save 10% gas.

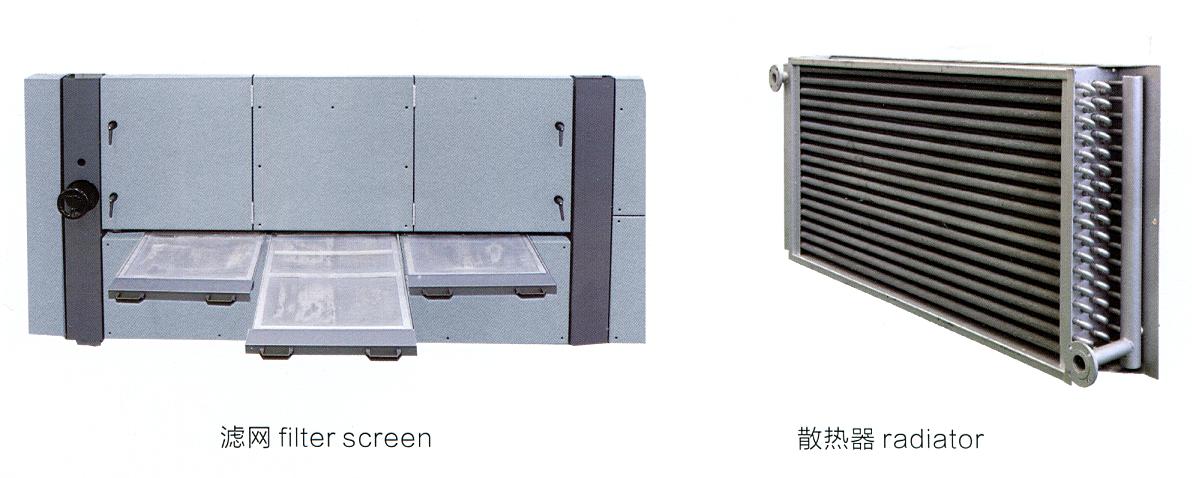

4. Cleaning: Through two layer strainer systems, cleaning during operation, to biggest limit protects waste pile from entering into chamber.

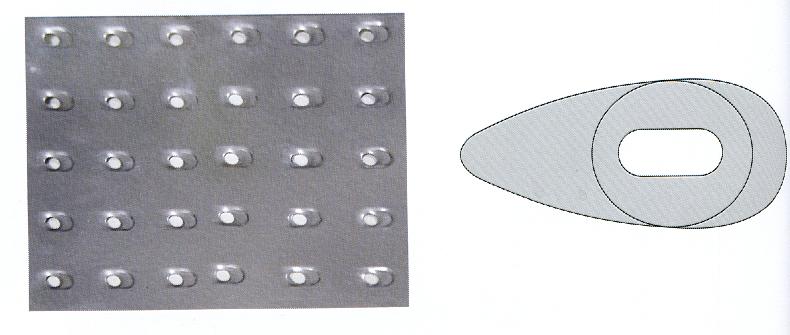

Nozzle Shape

Specially designed embossing nozzle: Hot air is vertically sprayed from the nozzle onto the surface of a fabric in the direction of its width. The specially designed embossing nozzle induces vertical spraying to ensure uniform density.

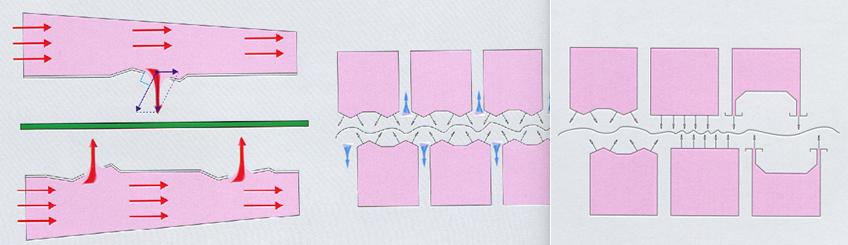

Nozzle Type

Nozzle structure optimized to the fabric: A peak type nozzle ideal for cotton knit, a flat type nozzle for general fabrics like synthetic fabrics and a slot type nozzle for fabrics with hair such as napped fabric and pile fabric are available. A nozzle suitable to the air flow volume and speed according to the processing properties is applied to ensure the best quality of the product.

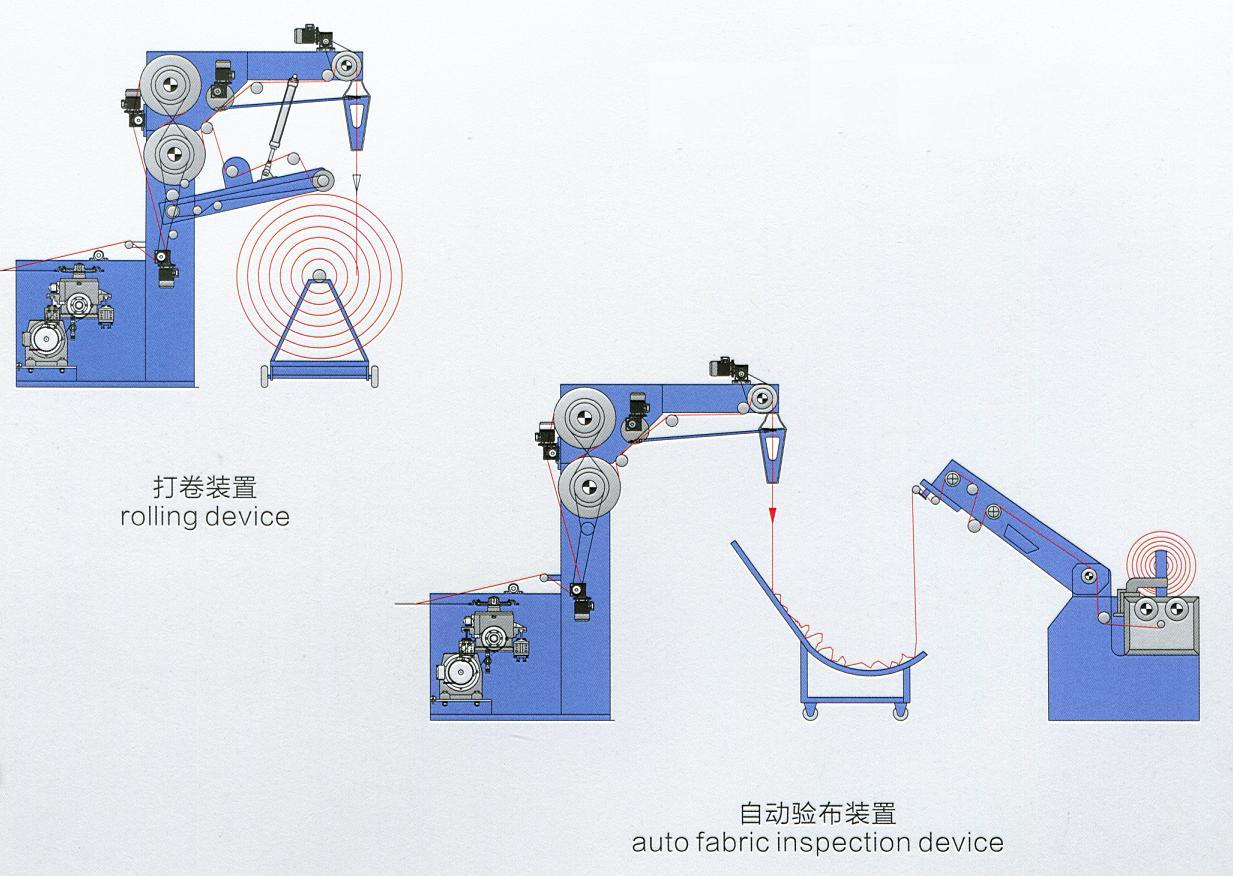

Fabric out Device

We provide different fabric out type for customer.

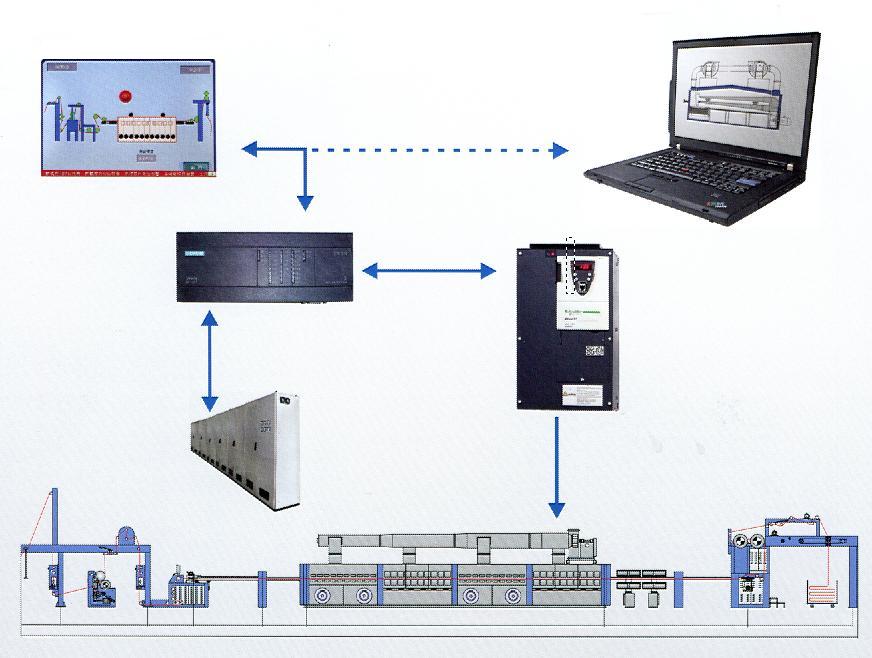

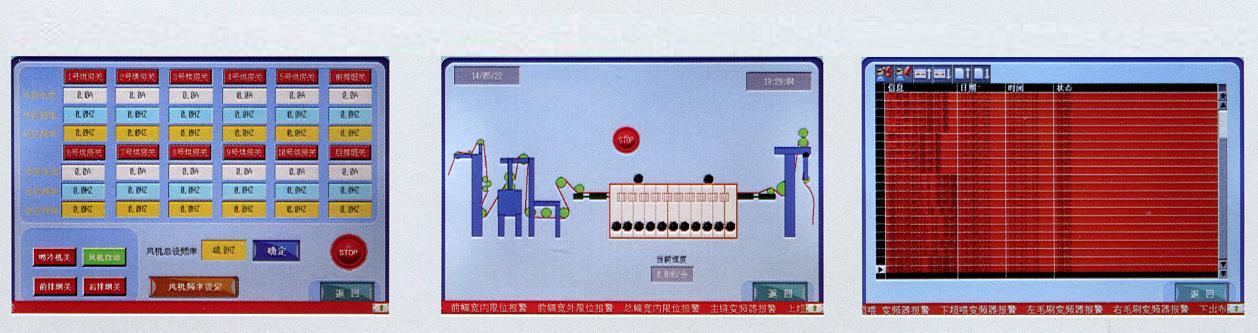

Electric Control

Reliable electric components are key point for machine stable running condition, humanized operation design and labor saving.

1. Touch screen control

2. Stenter speed setting

3. Overfeed ratio setting

4. Exhaust suction speed setting

5. Chamber temperature setting

6. Inner width adjustment

7. Different fabric craft storage

8. Machine fault display

Hot air braking resistance, solve air pipes trance.